Steel Commander Corp

Learning Center

We will answer any questions you have, give you advice on the best options to choose from, and provide timeframes for completion. You will have Steel Commander Corp as a partner for getting your new steel building. Contact us today.

Steel Commander Corp

Frequently Asked Questions

How Does a Steel Building Work?

Generally, there will be 5 key kinds of structural components that are crucial to making the sturdiest steel frame – compression members, bending members, tension members, combined force members, and their connections. The tension members are generally located as chord and web members in the trusses and open web steel joists. A tension member has one main objective, to carry tensile forces. In laymen’s terms, they are pulling forces only and their end connections are assumed to be pinned. Pin connections thwart and prevent any movement, rotations or shear forces from being applied to the member.

- Structural Framework:

- Primary Frame: The main structure of a steel building typically consists of columns, beams, and other elements that form the primary frame. These elements are designed to support the weight of the building and resist external forces like wind and seismic loads.

- Secondary Members: Secondary members, such as purlins and girts, are attached to the primary frame to provide additional support for the roof and wall panels.

- Foundations:

- Concrete Foundation: Like buildings made of other materials, steel buildings require a solid foundation. The foundation is usually made of concrete and serves to distribute the weight of the structure evenly to the underlying soil.

- Roof and Wall Systems:

- Roofing: The roof is supported by the structural framework and is designed to shed water and resist weather elements through the use of corrugated metal panels.

- Walls: The walls of a steel building are made of panels that are attached to the structural framework. The walls provide additional structural support and protection from the elements, along with optional insulation to maintain the comfort of your building.

- Cladding and Insulation:

- Cladding: Cladding refers to the outer layer of a building’s walls and roof that provide aesthetic appeal, weather resistance, and durability.

- Insulation: Insulation materials can be added between the layers of cladding to regulate temperature and improve energy efficiency. This is particularly important in buildings where climate control is necessary.

- Doors and Windows:

- Openings: Steel buildings incorporate openings for doors, windows, and other access points. These openings are designed in consideration of the building’s purpose and functionality.

- Framing for Openings: Additional framing, such as door jambs and window frames, is installed to support and secure openings in the walls.

- Connections:

- Bolts and Welds: Steel components are connected using bolts or welds. Bolts are often used for ease of assembly and disassembly, while welding provides a more permanent and robust connection.

- Flexibility and Expansion:

- Modularity: Steel buildings are modular, allowing for easy expansion or modification. Additional sections can be added to accommodate changing needs.

Why Choose Steel Over Wood Construction?

Steel buildings offer several advantages over wooden construction:

- Durability: Steel is a highly durable material, resistant to rot, mold, and pests that can affect wood. Steel structures typically have longer lifespans than wooden ones.

- Strength: Steel is much stronger than wood, allowing for larger open spaces without the need for support columns or load-bearing walls. This provides greater design flexibility and allows for more expansive interior layouts.

- Fire Resistance: Steel is non-combustible, whereas wood is highly flammable. Steel buildings offer superior fire resistance, reducing the risk of fire damage and enhancing safety.

- Minimal Maintenance: Steel structures require minimal maintenance compared to wood. They do not warp, shrink, or expand with changes in temperature and moisture, reducing the need for repairs and replacements over time.

- Faster Construction: Steel buildings can be prefabricated off-site and assembled quickly on-site, reducing construction time compared to traditional wooden construction methods. This can result in cost savings and faster project completion.

- Environmental Impact: Steel is a recyclable material, making it more environmentally friendly than wood. Additionally, steel buildings can be designed to be energy-efficient, with features such as insulated panels and reflective roofing materials, reducing energy consumption over the building’s lifespan.

- Long-Term Cost Savings: While steel buildings may have a higher upfront cost compared to wood, their durability and low maintenance requirements can result in long-term cost savings. Additionally, steel buildings may have lower insurance premiums due to their fire resistance and durability.

- Design Flexibility: Steel’s strength and versatility allow for a wide range of architectural designs and structural configurations. From industrial warehouses to modern office buildings, steel construction can accommodate various aesthetic preferences and functional requirements.

Overall, steel buildings offer superior durability, strength, safety, and sustainability compared to wooden construction, making them a preferred choice for many commercial, industrial, and residential applications.

Rigid Frame VS C-Channel Buildings

Rigid frame buildings offer superior strength, stability, and design flexibility, making them suitable for a wide range of commercial and industrial applications.

C-channel buildings provide a cost-effective solution with simpler construction and are ideal for smaller-scale projects where design flexibility is less critical.

- Rigid Frame Steel Buildings:

- Strength and Stability: Rigid frame steel buildings feature a primary framing system composed of rigid steel beams and columns. This design provides excellent strength and stability, allowing for larger clear spans without the need for interior support columns.

- Design Flexibility: Rigid frame buildings offer versatility in design, accommodating various architectural styles and functional requirements. They can be customized to meet specific project needs, including wide open floor plans, tall ceilings, and complex geometries.

- Fast Construction: Rigid frame steel buildings are typically prefabricated off-site and assembled quickly on-site, reducing construction time and labor costs.

- Durability: Due to their solid construction and minimal components, rigid frame steel buildings are highly durable and require minimal maintenance over their lifespan.

- Applications: Rigid frame steel buildings are commonly used for warehouses, manufacturing facilities, commercial buildings, aircraft hangars, and agricultural structures.

- C-Channel Steel Buildings:

- Cost-Effectiveness: C-channel steel buildings feature a framing system consisting of cold-formed C-shaped steel channels for beams and columns. This construction method can be more cost-effective than rigid frame buildings, making it suitable for budget-conscious projects.

- Lightweight: C-channel steel buildings are lighter in weight compared to rigid frame structures, which can simplify transportation and installation, especially in remote or challenging locations.

- Versatility: While not as versatile as rigid frame buildings, C-channel steel structures still offer some design flexibility and can be adapted to various building sizes and configurations.

- Ease of Assembly: C-channel steel buildings are relatively easy to assemble and can be erected quickly with minimal equipment and labor.

- Applications: C-channel steel buildings are often used for smaller industrial facilities, storage sheds, agricultural buildings, carports, and garages.

How Easy is the Assembly of a Steel Building?

The ease of assembling a steel building is one of the key advantages of choosing steel as a construction material. After the design phase is complete the pre-engineered steel building system is manufactured in sections and easy-to-assemble components. This makes the process of assembling a steel building much more time effective and straightforward compared to traditional construction methods. When your prefab steel building arrives, all you have to do is connect the parts and erect the building with either scaffolding and or a small crane, no special tools are required. We would also be able to get you in touch with a trusted MBCEA contractor in your area to make the build out process as seamless as possible. You would be able to view the full directory of those in your area through the link provided:

https://www.mbcea.org/member-directory

- Prefabrication:

- Components are Precut and Prefabricated: Our steel building components are manufactured off-site and delivered to your building site ready for assembly. This includes columns, beams, purlins, and other structural elements, which are often precut and prefabricated to exact specifications.

- Precision Engineering: Computer-aided design (CAD) and precision engineering ensure that components fit together seamlessly, reducing the need for on-site modifications.

- Bolted Connections:

- Bolting vs. Welding: Our steel building are pre-welded in the factory and utilize bolting when possible. Bolting allows for faster assembly as it eliminates the need for on-site welding, and it also facilitates disassembly if necessary.

- Ease of Adjustment: Bolts provide a degree of flexibility, allowing for adjustments during assembly if needed. This adaptability can be advantageous, especially in cases where site conditions may vary.

- Lightweight Components:

- Easy Handling: Steel components are relatively lightweight compared to other construction materials like concrete or masonry. This makes handling and positioning components easier, especially with the use of cranes and other lifting equipment.

- Modularity and Standardization:

- Modular Design: Steel buildings are designed with a modular approach, allowing for the construction of standardized sections. This modularity simplifies the assembly process and enables efficient replication of components.

- Standardized Components: The use of standardized components further streamlines the assembly process, as workers become familiar with the consistent design and specifications.

- Reduced Construction Time:

- Quick Construction Timeline: Due to the efficiency of prefabrication and ease of assembly, steel buildings have shorter construction timelines compared to traditionally built buildings.

- Weather Independence: The assembly of steel buildings is less dependent on weather conditions compared to traditional construction methods. This can contribute to faster project completion.

How Customizable is a Steel Building?

Steel buildings are highly customizable, offering a wide range of design options to meet specific requirements and preferences. The versatility of steel as a construction material allows for flexibility in terms of size, shape, layout, and aesthetic features. Our designers will work with you to design your door and window openings, whiling maintain the structural safety of your building.

- Size and Dimensions:

- Steel buildings can be customized to accommodate various sizes, from small structures like garages and storage sheds to large industrial warehouses or aircraft hangars.

- Design and Architecture:

- The design of a steel building is highly customizable. Architectural features, such as roof styles, wall panels, doors, windows, and facade details, can be tailored to meet specific aesthetic preferences and functional needs.

- Interior Layout:

- The interior layout of a steel building can be designed to suit the intended use. Steel structures often allow for open, column-free spaces, providing flexibility in arranging interior spaces for offices, production areas, storage, or other purposes.

- Roof Styles:

- Steel buildings can have various roof styles, including gable roofs, hip roofs, or even more complex designs. The choice of roof style can impact the building’s appearance and functionality.

- Color and Finishes:

- Steel building components, such as wall panels, roofing, and trim, can be coated in a variety of colors. This allows for customization to match corporate branding, blend with the environment, or achieve a specific aesthetic appeal.

- Insulation Options:

- Insulation materials and methods can be customized based on climate considerations and energy efficiency goals. Different insulation options can be integrated into the walls and roof to regulate temperature and reduce energy consumption.

- Doors and Windows:

- Steel buildings can have various types and sizes of doors, windows, and entry points. The placement and design of these elements can be customized based on the building’s function and the desired level of natural light and ventilation.

- Foundation Options:

- Depending on site conditions and building requirements, different foundation types, such as monolithic slabs, concrete slabs, or pier foundations, can be customized for the steel building.

- Modular Construction:

- Steel buildings often use modular construction methods, allowing for easy expansion or modification. Additional sections or components can be added to the existing structure to accommodate changing needs.

What Are the Most Common Sizes?

Metal buildings are highly versatile due to their many end-use applications. They can easily and precisely meet your dimensional needs no matter the scale. Your steel building can be hundreds of feet wide and deep, while easily reaching heights of forty feet. These steel building systems permit you to always add more and more mainframe components and beams to add length or width. You also enjoy the added flexibility to adjust the roof pitch, as well as the end wall design with overhead awnings or roofing. We custom build all of our buildings to meet your needs perfectly.

Our Buy and Build page details our most popular sizes and average associated pricing. You can access that page through the “Building Sales” tab or through the link provided: https://steelcommandercorp.com/buy-metal-buildings/

Average sizing for various steel applications throughout the community are as follows:

- Small to Medium-Sized Buildings:

- Width: 30 feet to 80 feet

- Length: 30 feet to 200 feet

- Height: 10 feet to 30 feet

- Standard Warehouse or Industrial Buildings:

- Width: 80 feet to 150 feet

- Length: 100 feet to 300 feet

- Height: 20 feet to 40 feet

- Agricultural Buildings (e.g., Barns):

- Width: 40 feet to 80 feet

- Length: 60 feet to 150 feet

- Height: 12 feet to 30 feet

- Commercial Retail Buildings:

- Width: 50 feet to 100 feet

- Length: 80 feet to 200 feet

- Height: 12 feet to 20 feet

- Aircraft Hangars:

- Width: 80 feet to 150 feet

- Length: 100 feet to 300 feet

- Height: 20 feet to 40 feet

- Sports Facilities (Indoor Sports Arenas):

- Width: 100 feet to 200 feet

- Length: 150 feet to 300 feet

- Height: 30 feet to 60 feet

- Office Buildings:

- Width: 60 feet to 100 feet

- Length: 80 feet to 200 feet

- Height: 12 feet to 20 feet

- Auto Repair Shops / Garages:

- Width: 30 feet to 80 feet

- Length: 40 feet to 150 feet

- Height: 12 feet to 20 feet

- Residential Garages / Storage Sheds:

- Width: 20 feet to 40 feet

- Length: 20 feet to 80 feet

- Height: 8 feet to 16 feet

Are Steel Buildings Cost Efficient?

Each steel building home is unique and cost varies depending on location and end-use. Meeting the state (Registered Engineering in All 50 States) and local requirements also contributes to overall cost. Building code inspections are a breeze as most inspectors know there will be little to question with a prefab steel building that has been already approved at the state level.

The overall consensus from steel building home buyers is that they cannot be more satisfied with the cost and rapid delivery. Optimism for steel building homes is gaining more and more steam every day, as the most affordable way to construct a home at an unbelievably affordable price.

Final building price may vary and is based on several factors such as geographic location, end-use, wind/snow or other structural load requirements in order to meet local and state approval requirements. Additionally, extra and optional features or add-ons may be an added cost. Be sure to contact a Steel Commander building specialist to finalize the price of your new steel building.

These are just a few reasons why steel buildings are so cost-effective:

- Construction Speed:

- Steel buildings can be erected quickly compared to traditional construction methods. The use of prefabricated components and modular construction techniques contributes to faster project completion, reducing labor costs and the overall construction timeline.

- Material Costs:

- Steel is a cost-efficient material for construction due to its strength-to-weight ratio, durability, and availability. The ability to order pre-engineered steel components in bulk can lead to additional cost savings.

- Design Flexibility:

- Steel allows for flexible and open design concepts, reducing the need for interior support columns. This adaptability often results in more efficient use of space and can lead to cost savings in terms of material requirements.

- Durability and Low Maintenance:

- Steel buildings are known for their durability and resistance to various environmental factors, such as termites, rot, and mold. The low maintenance requirements contribute to long-term cost efficiency by reducing the need for repairs and replacements.

- Energy Efficiency:

- Properly insulated steel buildings can be energy-efficient, leading to cost savings on heating and cooling expenses. Steel structures can easily accommodate insulation materials, and reflective roofing options can contribute to a more energy-efficient building envelope.

- Sustainability:

- Steel is a highly recyclable material, and many steel buildings incorporate recycled content. The sustainable and eco-friendly nature of steel can contribute to cost efficiency, especially as environmental considerations become more significant in construction.

- Long Lifespan:

- Steel buildings have a long lifespan, often exceeding that of some other construction materials. The durability of steel contributes to reduced lifecycle costs, as the building requires fewer replacements or major renovations over time.

- Insurance Cost:

- Insurance costs for steel buildings are often lower than those for structures made from certain other materials. The resistance of steel to fire, pests, and environmental hazards can result in reduced insurance premiums.

- Resilience to Extreme Conditions:

- Steel buildings are engineered to withstand extreme weather conditions, making them a suitable choice for areas prone to hurricanes, earthquakes, or heavy snow loads. The resilience to these conditions can contribute to long-term cost efficiency.

- Prefabrication and Modular Construction:

- Prefabrication of steel components off-site and modular construction methods can lead to cost savings by minimizing on-site labor requirements, reducing waste, and improving construction efficiency.

Are Steel Buildings More Energy Efficient Than a Traditionally Built Building?

Steel buildings are incredibly energy efficient; both during the manufacturing process and with heating/cooling. Not only that, did you know 98% of steel we use every day is recycled?

Steel buildings are inherently more energy-efficient than structures made from other materials; their energy efficiency depends on factors like design, insulation, and construction quality. Steel buildings offer advantages such as thermal efficiency, design flexibility for energy-efficient features, durability, and the potential for solar panel installation. Achieving energy efficiency in steel buildings requires careful design, insulation, and adherence to building codes and energy standards, making it essential to consider various factors beyond just the material used. Listed below, you will find just some of the advantages of energy efficiency in steel buildings:

- Thermal Performance:

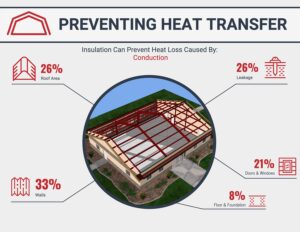

- Insulation: Steel buildings can be effectively insulated to reduce heat transfer, maintaining a comfortable indoor temperature and reducing energy consumption for heating and cooling.

- Cool Roofing: Metal roofing materials with reflective coatings can contribute to energy efficiency by reducing heat absorption and minimizing the need for air conditioning.

- Precision Engineering:

- Tight Construction: Steel buildings are precision-engineered, leading to a tight and well-sealed envelope. This reduces air infiltration, improving energy efficiency.

- Design Flexibility:

- Optimized Designs: Steel allows for long spans and open spaces without the need for many interior support columns. This flexibility in design can optimize natural lighting and ventilation, reducing the need for artificial lighting and HVAC systems.

- Durability and Longevity:

- Low Maintenance: Steel structures typically require less maintenance than some traditional building materials, leading to sustained energy efficiency over time.

- Resistance to Decay: Unlike some traditional materials, steel is not susceptible to rot, mold, or termite damage, ensuring the long-term performance of the building envelope.

- Recyclability:

- Sustainable Practices: Steel is highly recyclable, and many steel buildings incorporate recycled content. This contributes to sustainability efforts and reduces the environmental impact of construction.

- Prefabrication:

- Efficient Construction: The prefabrication of steel components off-site can lead to faster construction times, reducing the energy expended during the construction phase.

How Easy is It to Install Solar Panels?

Please Note: Please consult with a licensed electrician to install your solar panels. Steel Commander Corp does not offer solar panel installation services. The information below is purely for general information and may not apply to your particular solar system.

Most solar panel companies make it easy to install specialized brackets onto the structure of the building. From there, the solar panels can be easily attached to the brackets. Check with your solar panel contractor for specifics on how they will install them.

- Structural Assessment:

- Before proceeding with solar panel installation, conduct a structural assessment of the steel building to ensure that it can support the additional weight of the solar panels and any related equipment. Consult with a structural engineer to determine the load-bearing capacity.

- Roof Inspection:

- Inspect the roof to identify its condition and suitability for solar panel installation. Check for any damage, leaks, or areas that may need repairs before the installation.

- Orientation and Tilt:

- Determine the optimal orientation and tilt for the solar panels based on the building’s location and solar exposure. Ideally, solar panels should face south or southwest in the Northern Hemisphere and north or northwest in the Southern Hemisphere.

- Shading Analysis:

- Conduct a shading analysis to identify potential obstructions, such as nearby buildings or trees, that could cast shadows on the solar panels. Minimizing shading is crucial for maximizing energy production.

- Permitting and Regulations:

- Obtain the necessary permits and comply with local building codes and regulations. This may involve submitting plans for the solar panel installation to the local authorities for approval.

- Design and Layout:

- Work with a solar energy system designer to create an efficient layout for the solar panels. Consider factors such as panel orientation, spacing, and electrical connections. Ensure that the design integrates well with the steel roof.

- Mounting System:

- Choose an appropriate mounting system for the solar panels. Common options include ballasted mounts, penetrating mounts, or hybrid systems that combine both. The choice depends on the roof type, load-bearing capacity, and local conditions.

- Roof Preparation:

- Prepare the roof surface by ensuring it is clean and free of debris. If needed, make any necessary repairs to the roof before installing the mounting system.

- Solar Panel Installation:

- Install the mounting system according to the design specifications. Attach the solar panels securely to the mounts. Electrical wiring and connections should be done according to industry standards.

- Inverter Installation:

- Install inverters to convert the direct current (DC) produced by the solar panels into usable alternating current (AC) for use in the building or for feeding back into the grid.

- Electrical Wiring:

- Connect the solar panels to the inverter and ensure proper electrical wiring. Implement safety measures, such as grounding, to comply with electrical codes.

- Monitoring System:

- Install a monitoring system to track the performance of the solar panels. This can help identify any issues and optimize energy production.

- Commissioning:

- Test the entire solar energy system to ensure it is functioning correctly. This may involve working with a qualified technician or electrician to verify electrical connections and system performance.

- Maintenance Plan:

- Establish a routine maintenance plan to ensure the continued efficiency and longevity of the solar panels. Regular inspections and cleaning may be necessary.

- Connect to the Grid (if applicable):

- If the intention is to feed excess energy back into the grid, coordinate with the local utility company to connect the solar energy system to the grid.

What Are the Insulation Options for a Steel Building?

Ordering insulated panels during the design phase is much easier when done on the front end. The cost is slightly more than roll insulation, though insulated panels have been designed specifically for steel buildings, providing a much tighter fit against the ceilings and walls.

Insulating your steel building is key to creating a comfortable environment through all weather conditions. Everything from the roof to the floor should be considered when designing your building.

Wall Insulation:

- Steel framing conducts heat, so it’s essential to insulate between the steed studs or framing members to break this thermal bridge.

Roof Insulation:

- Investing in an insulated roof aids in maintaining a comfortable and consistent interior space by preventing energy loss caused by warm air rising during those cold winter months.

Floor Insulation:

- Depending on the design of the steel home, you may need to insulate the floor to prevent heat loss to the ground or to create a comfortable living environment over a concrete slab.

Air Sealing:

- In addition to insulation, effective air sealing is essential to prevent drafts and energy loss. Seal gaps, cracks, and penetrations with caulk or expanding foam.

Vapor Barrier:

- A vapor barrier can be important in steel homes to control moisture. It should be placed on the warm side of the insulation to prevent condensation within the wall or ceiling.

Soundproofing:

- Insulation can also provide soundproofing benefits. If noise control is a concern, consider using acoustic insulation in walls or ceilings.

Give us a call at 844.722.4766 to discuss more details.

Does a Steel Building Have Ventilation?

Ventilation in a steel building is crucial for maintaining a comfortable and healthy indoor environment. Proper ventilation helps control temperature, humidity, and air quality, ensuring the well-being of occupants and the longevity of the building structure. Here are some considerations for ventilation in a steel building:

- Natural Ventilation:

- Roof Vents: Installing roof vents can allow hot air to escape, promoting natural airflow. Ridge vents or turbine vents are common choices.

- Louvers: Placing louvers or vents on the walls can facilitate the intake of fresh air. Louvers can be positioned strategically to allow air circulation while preventing rain or snow from entering.

- Mechanical Ventilation:

- Exhaust Fans: Mechanical exhaust fans can be installed to actively remove stale air and promote air exchange. Fans can be placed at key locations to optimize airflow.

- Intake Fans: In conjunction with exhaust fans, intake fans can be strategically placed to bring in fresh air. This balanced approach helps maintain proper air circulation.

What Are My Color Options?

We have a plethora of color options from which to choose from for your end wall and trim colors. There are literally hundreds of color combinations available for you to create the ideal aesthetic for your steel building. We use only the highest quality paints, coupled with the latest silicone protected polyester technology available on the market today. The Energy Star Approved paint will create a thermal barrier because of its ability to reflect up to seventy percent of the sun’s rays, while also keeping energy from escaping.

You are able to utilize our virtual design portal to design a custom building to submit for a free quote. This tool allows you to create exactly what you need, including colors and specific exterior finishes. You can access that portal on our website under the tab, “Design Your SCC Building,” or through the link provided: https://steelcommandercorp.actbuildingsystems.com/

What Are My Entry Way Options?

When we design your steel building, you will have greater flexibility for customization. The end walls of the building can even incorporate walk through doors in 3′ x 7′ 3070/single leaf to 6′ x 7′ 6070/single leaf insulated walk through doors. Overhead doors that roll up, bi-fold, slide doors, and sections can be used for entryways.

Sliding doors are utilized heavily in the equine industry when constructing horse barns and riding arenas. They are quiet and manually opened and closed with little effort. Bi-fold doors consist of 2 panels that are hinged at the top, which allows for a larger opening for planes and bigger vehicles. Sectional doors utilize horizontal sections, which are hinged together and electronically operated in the same manner as your home garage door. Metal roll-up doors are constructed with the exact same mechanical concept, but sectional doors have much smaller horizontal sections but they are far more rugged by utilizing 18 to 20 gauge galvanized steel.

What Can I Expect in the Interior?

The interior for your steel building is a clear span structure with one hundred percent usable interior space. Controlling the climate is easily done with insulated panels, along with the addition of climate controls for adjusting temperature. Your steel building is fully customizable and can adapt to whatever your desired needs are for the interior infrastructure.

We supply everything you would need to get your building erected, but you would need a secondary contractor to do the build out and interior finishes. We would be able to get you in touch with a trusted MBCEA contractor in your area to make this process as seamless as possible. You would be able to view the full directory of those in your area through the link provided:

https://www.mbcea.org/member-directory

Do Steel Buildings Have Foundation Requirements?

An existing monolithic slab, concrete slab or a floating slab foundation will need to be in place before constructing your steel building. Your foundation is generally poured according to your geography, building size, weight, irrigation, frost lines, and other pertinent factors. Once you have an approved foundation in place the building is then bolted down to the foundation for a secure and permanent building.

- Monolithic Slab Foundation:

- Description: A monolithic slab is a single, continuous layer of concrete that serves as both the floor and foundation of a building. It is poured all at once, including the footings.

- Construction: The construction involves excavating the site, preparing the ground, adding a layer of gravel, and pouring the concrete directly on the prepared ground.

- Advantages:

- Cost-effective and straightforward construction.

- Suitable for stable soil conditions.

- Often used in residential construction, especially for single-story homes.

- Concrete Slab Foundation:

- Description: A concrete slab foundation consists of a horizontal layer of concrete that is typically thicker than a monolithic slab. It is poured on top of a layer of gravel or compacted soil, and it may have additional components like footings.

- Construction: The construction involves site preparation, adding a layer of gravel, installing formwork (if needed), placing reinforcement (if required), and pouring the concrete.

- Advantages:

- Suitable for a variety of building types, including residential and commercial structures.

- Can accommodate larger buildings and heavier loads compared to monolithic slabs.

- Provides a stable and durable foundation.

- Floating Slab Foundation:

- Description: A floating slab foundation is a type of foundation that does not have footings and is not attached to the building’s walls. It is typically used in regions with expansive soils to minimize the impact of soil movement on the structure.

- Construction: The construction involves excavating, preparing the ground, adding a layer of gravel, and pouring a reinforced concrete slab that “floats” on the soil surface without being directly connected to the building.

- Advantages:

- Minimizes the impact of soil expansion and contraction.

- Reduces the risk of foundation movement in expansive soil conditions.

- Suitable for areas with high clay content in the soil.

Considerations for Choosing a Foundation Type:

- Soil Conditions:

- Monolithic slabs and concrete slabs are suitable for stable soil conditions.

- Floating slabs are often chosen in areas with expansive soils or when dealing with potential soil movement issues.

- Building Size and Load:

- Monolithic slabs are often used for smaller structures, while concrete slabs can accommodate larger buildings and heavier loads.

- Floating slabs are suitable for various building sizes, with a focus on mitigating soil-related issues.

- Cost and Construction Speed:

- Monolithic slabs are often the most cost-effective and quick to construct.

- Concrete slabs may be more expensive but provide additional load-bearing capacity.

- Floating slabs can be cost-effective in regions with challenging soil conditions.

- Local Building Codes:

- Building codes and regulations in your area may influence the choice of foundation type.

- Site Characteristics:

- Site-specific factors, such as the presence of trees, water tables, or nearby structures, can impact the choice of foundation.

What Does the Ordering Process Entail?

If you decide to make the decision to order a steel building, there are multiple options ranging from different structural features, gauge steel, colors, functionality, accessories, size and more. Our knowledgeable staff of consultants, engineers, and technicians are here to assist you with planning and pricing.

You can reach us anytime at 844.722.4766 to discuss.

Why Do Prices Depend on My Location?

Prices depend on your location due to the differences in state and county building regulations. Building codes are regulations set by local authorities to ensure the safety, health, and welfare of the public within the built environment. These codes specify the minimum standards for construction and cover aspects such as structural design, fire safety, electrical systems, plumbing, and more.

Here’s how county building codes can influence steel building prices:

- Design Requirements:

- Local building codes may have specific design requirements that affect the engineering and design of steel buildings. For example, wind and snow load requirements, seismic considerations, and other structural factors can influence the design and engineering of a steel building to ensure it meets the local code requirements.

- Permitting Fees:

- Obtaining the necessary permits to comply with building codes often involves fees. These fees can vary based on the size and complexity of the project. The permitting process ensures that the construction plans meet local codes and regulations.

- Code Compliance Materials:

- Meeting specific building code requirements may necessitate the use of certain materials or construction methods. This can impact the choice of steel components, insulation materials, roofing systems, and other elements, potentially affecting the overall cost.

- Environmental and Energy Efficiency Standards:

- Some local building codes include requirements related to energy efficiency, environmental sustainability, and the use of renewable energy. Compliance with these standards may involve additional costs for features such as insulation, reflective roofing, or renewable energy systems.

- Inspections and Testing:

- Local building codes often require inspections and testing during and after construction to ensure compliance. The costs associated with these inspections, as well as any necessary modifications to meet code requirements, can impact the overall project cost.

- Zoning Regulations:

- Zoning regulations, which are often part of local building codes, can dictate how land and buildings can be used in certain areas. Compliance with these regulations may impact the size, height, and placement of a steel building on the property.

- Accessibility Standards:

- Building codes may include accessibility standards to ensure that structures are accessible to individuals with disabilities. Compliance with these standards may require the inclusion of features such as ramps, accessible restrooms, and wider doorways.

- Fire Safety Requirements:

- Fire safety standards, including the use of fire-resistant materials and the inclusion of fire suppression systems, can affect the construction and cost of a steel building.

What Are My Financing Options?

At Steel Commander Corp, we pride ourselves in making your metal building purchase as stress-free as possible. No matter what your financial situation may be, we want to make it easier for you to afford the metal building of your dreams for a price you can afford. Fund your project as soon as tomorrow. Finance your steel building today!

You would be able to see if you qualify with our lending partner through the link provided:

Give us a call at 844.722.4766 with any questions you may have.

*60 seconds pre-qualification. Does not affect credit score.

What is Galvalume Steel?

Galvalume steel is a type of steel product that is coated with a combination of aluminum, zinc, and sometimes silicon. This coating provides enhanced corrosion resistance compared to traditional galvanized steel. The name “Galvalume” is a combination of “galvanized” and “aluminum.”

The coating composition of Galvalume steel typically consists of:

- 55% Aluminum: The majority of the coating is made up of aluminum, which provides excellent corrosion resistance.

- 43.5% Zinc: Zinc enhances the corrosion resistance of the steel, especially in areas where the aluminum coating may be damaged.

- 1.5% Silicon: Silicon is sometimes included in the coating to improve adhesion and durability.

The combination of these materials creates a protective barrier that helps prevent rust and corrosion, making Galvalume steel suitable for various applications in construction and manufacturing.

Advantages of Galvalume steel include:

- Improved Corrosion Resistance: Galvalume steel offers better corrosion resistance compared to traditional galvanized steel.

- Heat Resistance: It has good heat resistance, making it suitable for applications where exposure to high temperatures is a concern.

- Longevity: Galvalume-coated steel has a longer lifespan compared to some other types of coated or untreated steel.

- Aesthetics: Galvalume has a characteristic appearance with a shiny surface that can be appealing in architectural and construction applications.

Common applications of Galvalume steel include roofing and siding in areas where exposure to harsh weather conditions or corrosive elements makes durability and corrosion resistance essential.

Steel Commander Corp

Steel Building Colors

Endwall Colors

- #e7e7e9

Polar White

SCC-1605

- #b2b4b3

Pearl Gray

SCC-1625

- #878684

Slate Gray

SCC-1925

- #dad7cd

Light Stone

SCC-1205

- #bda885

Sahara Tan

SCC-1914

- #a52923

Brite Red

SCC-0204

- #4c7695

Hawaiian Blue

SCC-0802

- #184162

Gallery Blue

SCC-0705

- #758576

Colony Green

SCC-0314

- #5f5751

Burnished Slate

SCC-0205

- #803b3f

Rustic Red

SCC-1804

- #204232

Fern Green

SCC-0614

Trim Colors

- #e7e7e9

Polar White

SCC-1605

- #b2b4b3

Pearl Gray

SCC-1625

- #878684

Burnished Slate

SCC-1925

- #dad7cd

Light Stone

SCC-1205

- #bda885

Sahara Tan

SCC-1914

- #204232

Fern Green

SCC-0614

Note: Every effort has been made to display colors accurately, however, colors shown may differ from actual colors due to variations in color monitors and web page displays. Call for our brochure to view color swatches: 1-844-SCC-IRON

Steel Commander Corp

Steel Building Downloads

Steel Commander Corp

Steel Building Video Gallery

Get a Quote Today

Schedule a free Consultation

We will answer any question you have, give you advice on the best options to choose from, and time estimates. You will have Steel Commander Corp as a partner for getting your new steel building. Contact us today.

Metal Building Contractors & Erectors Association

Metal Building Contractors & Erectors Association USGBC

USGBC Energy Star

Energy Star CWB

CWB Certified CSA A660

Certified CSA A660 AWS

AWS- Proud Sponsor of MotoAmerica and the Steel Commander Stock 1000